The complete restoration of this house lasted approximately one year and involved about ten full-time individuals, excluding external interventions such as the surface treatment of metallic parts.

With a view to long-term preservation respecting the integrity of the edifice, there was no other option but to undertake a complete restoration, akin to that of a collector’s vehicle. This museum-quality restoration was carried out with extreme professionalism and meticulous attention to detail. Indeed, Gérard Pannetrat (a sheet metal worker and coachbuilder from automotive prototyping), who served as the project manager, supervised the operations from start to finish: from the dismantling of the three houses in Africa to their current reassembly.

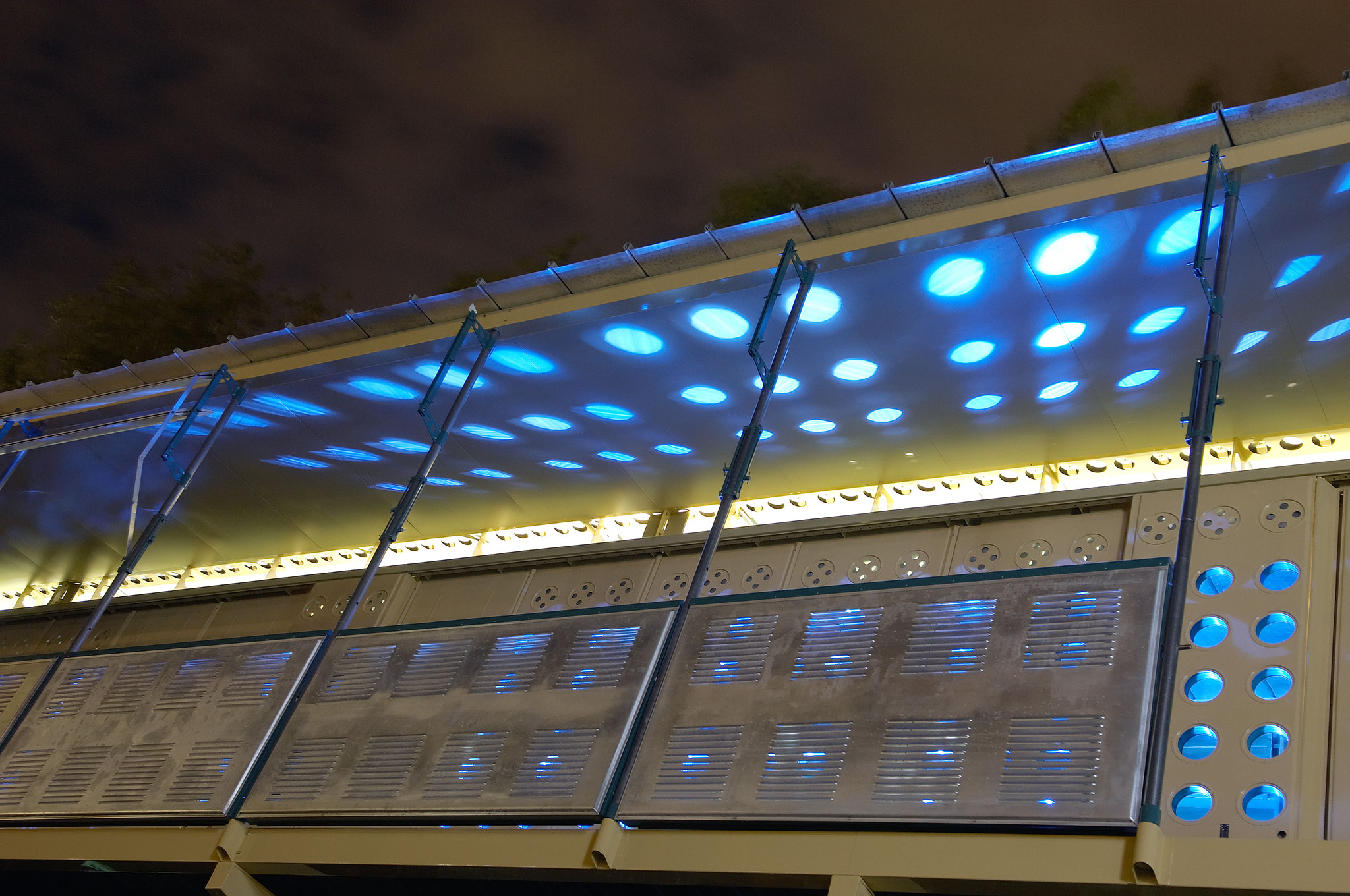

This intimate knowledge of each piece of this puzzle helped avoid many errors. Such as the exact reproduction of the original polychromy: sand for the exterior walls, green for the interior, light beige for the false ceilings, and duck egg blue for the exterior posts. Similarly, the continuity of the interior steel flooring extending to the two end balconies is a detail that might have escaped an amateur restorer but not Gérard Pannetrat…

All components of the house were scrupulously preserved, including the most corroded ones. However, given the fragility of the steel sheet elements of the load-bearing platform, we decided to remake them identically, thus allowing the house to be exhibited outdoors and ensuring its safe use once again.

The axial porticos and the steel sheet framework were in very good condition and only required a surface treatment. We preserved one of the legs of one of the porticos as is, after appropriate stripping, attesting to its good preservation.

The aluminum sheet cladding elements – facade panels, doors, railings, and roof trays – were also well preserved. However, very extensive bodywork was necessary to overcome all the impacts, scratches, bullet marks, and tears caused by time and human activity.

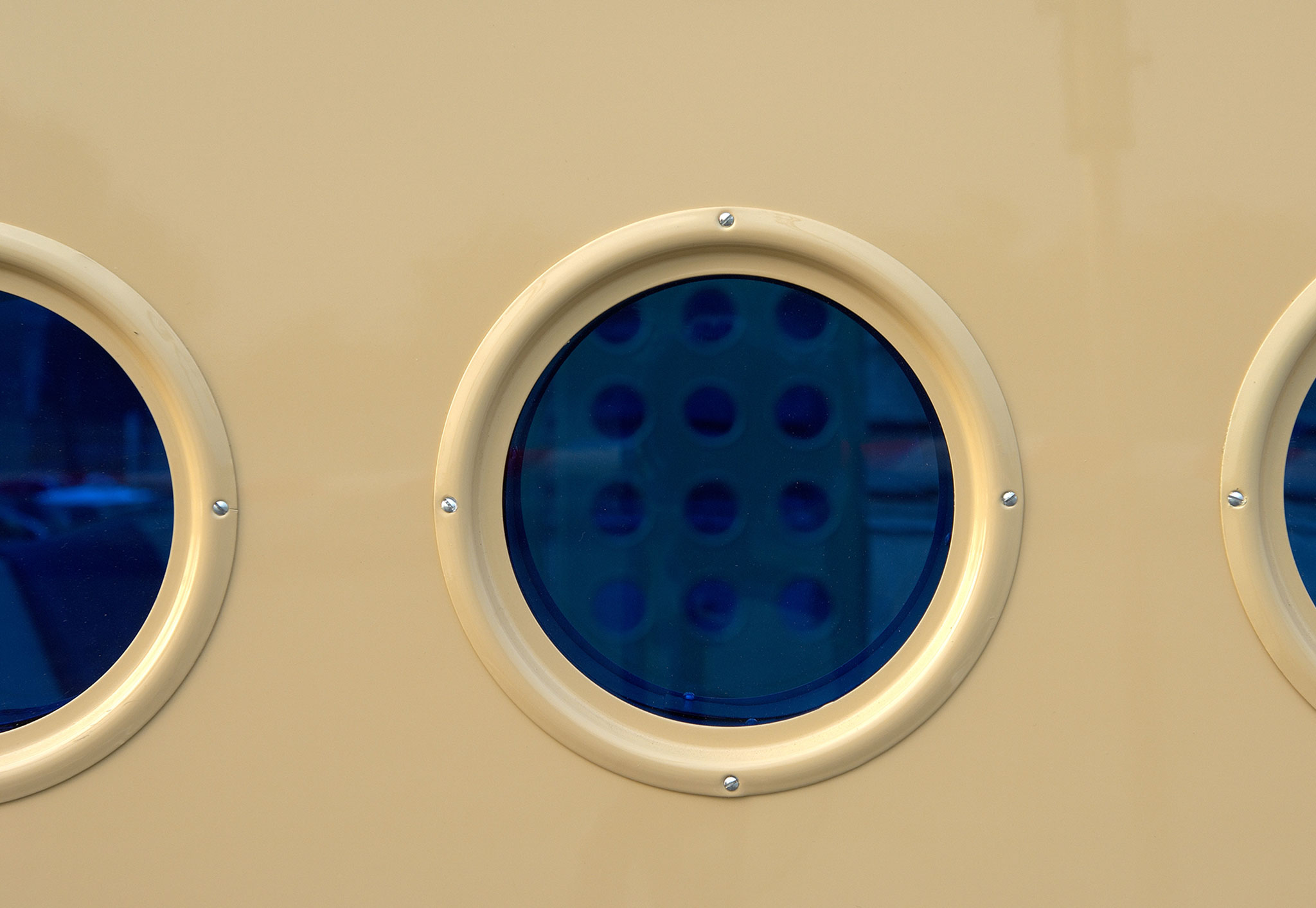

Some severely damaged elements, such as certain porthole panels – later perforated to embed air conditioners – were carefully preserved, with the missing parts identically remade and then grafted.

The grating slats were originally made of solid oak, shipped from France with the houses. Most had been replaced by locally manufactured iroko slats, which we had completed on site.

The rock wool insulation was entirely replaced inside the doors, facade panels, and false ceilings.

On site, the houses were installed on reinforced concrete stilts connected to masonry foundations.

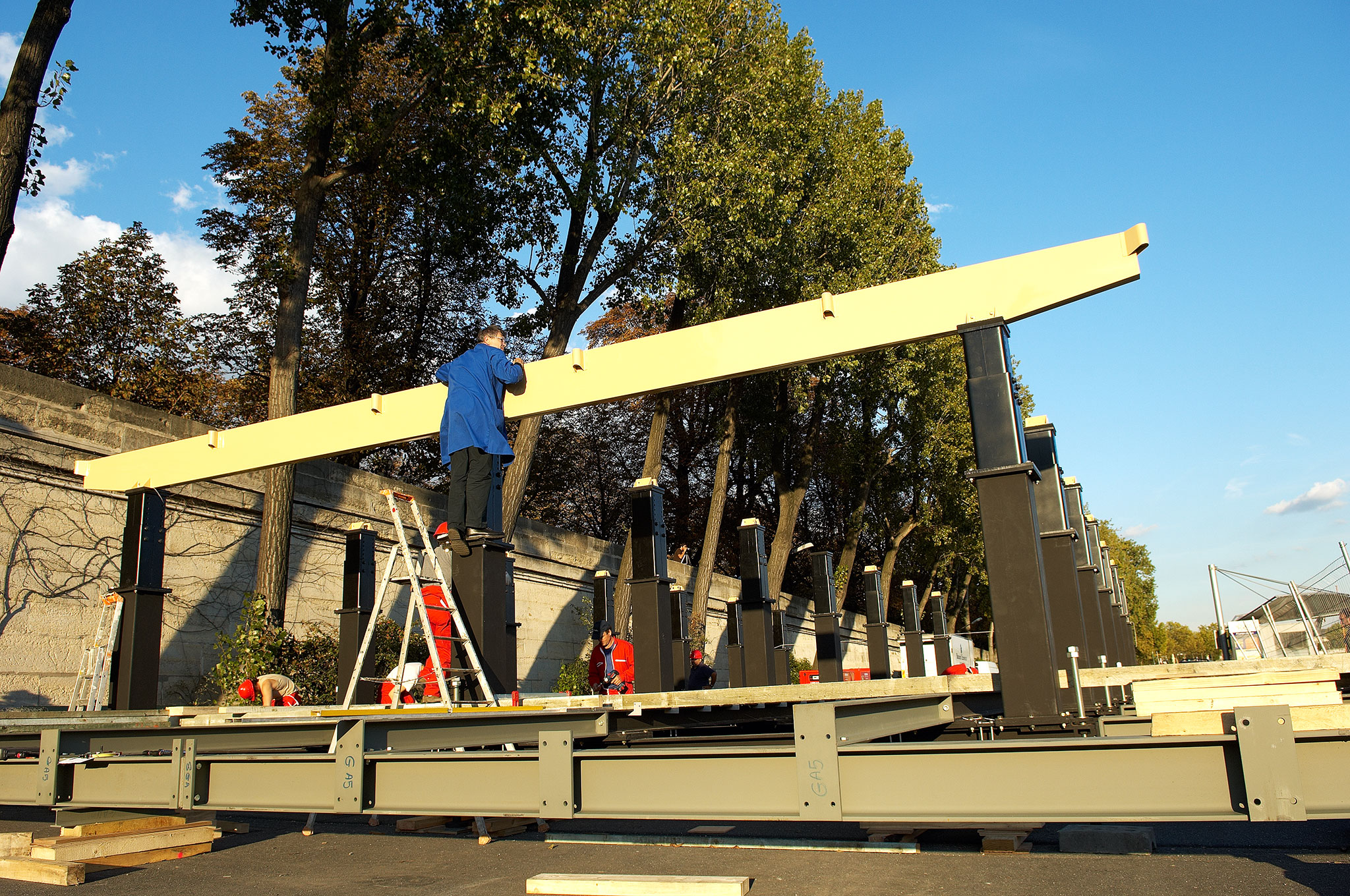

In order to dismantle, transport, and reassemble the house in a few days, while ensuring foundations capable of withstanding the most violent natural phenomena, a removable platform consisting of a bolted steel beam grid was custom-designed and manufactured.

The 21 steel stilts bolted to the ground structure are designed to allow the house’s height to be adjusted from 0.60 m to 3.50 m.

Unavailable